Install Corrugated Metal Roofing. EASY VIDEO Screw Placement +Screw Location + Overlapping Panels

Install Corrugated Metal Roofing. Learn About Screw Placement And Overlapping The Corrugated Roofing Panels. This video covers the installation of fasteners on 7/8" Corrugated exposed fastener metal roofing panels

In this video you will learn about:

• Overlapping Corrugated Metal Roofing

• Do You Locate Fasteners In The High Or Low? Why?

• Screw Location

• Screw Line Spacing

• How Many Screws Do I Need?

If you already have not purchased your metal roofing give us a chance to bid your job. Save 15% to 50% with our manufacturer direct pricing and great customer service. Inexpensive delivery anywhere within the United States.

00:00 How to install corrugated metal roofing

00:43 How to overlap corrugated metal roofing panels

01:06 Corrugated metal roofing coverage

01:32 Do the screws go in the tops or bottom of corrugated metal roofing?

01:45 Why do the screws go in the high of the corrugated?

02:12 What is the screw placement on corrugated metal roofing?

02:31 What is a screw line on a metal roof?

02:41 What is the screw pattern for corrugated metal roofing?

03:19 How far apart do you put screws in metal roofing?

03:29 What is the screw line spacing corrugated metal roofing?

04:33 Screw line spacing corrugated on metal purlins

04:48 How many screws will I need on a corrugated metal roof?

Visit Our WEBSITE

Visit our LEARNING CENTER

WRITTEN GUIDE – Screw Placement

DIAGRAM – Screw Placement

39" Wide Panel

37" Wide Panel

Download Our Install Guide

7/8" Corrugated

How Many Screws Do I Need For Metal Roofing?

When you learning how to install corrugated metal roofing it's important to install the screws and fasteners correctly. Here some installation tips that will help you with your metal roof installation.

Screw Spacing & Screw Placement Best Practices

It can be confusing trying to figure out the correct way to screw down a metal roof. You do not know where to put the screws, how often to fasten the metal roofing panels, and then you have to figure out how many screws to purchase. Don’t worry though because we have you covered. It’s actually a really simple process and we will guide you through it step by step. Once you watch this video you will be an expert.

It is easy to determine where the screws should be located on your metal roofing panel. Every panel will have a different screw placement diagram. These will be located within the installation guide. First, we will review the screw placement for the most common metal roofing panels, starting with ⅞” corrugated.

Where To Place Screws For ⅞” Corrugated

The screw placement for ⅞” corrugated can be a little tricky. The fasteners are located in different locations for roofing and metal siding conditions. Then if that wasn’t confusing enough metal roofing manufacturers have differing opinions on the correct corrugated screw placement for a roofing condition. Hang in there and we will explain this one to you in detail.

There are two schools of thought when it comes to corrugated metal roofing screw placement. Both are correct.

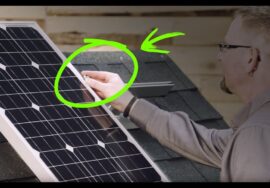

Installing the metal roofing screw in the high of the corrugated panel as shown below. The advantage to this method is the screws are exposed to less water and debris. The main disadvantage is a less secure connection.

Screws that are installed in the low of the metal roofing panel will result in a more secure connection, but will be less weather tight. The screw will compress better when attached in the low and you are less likely to distort the metal roofing panel when you tighten the screw.

If the fastener is placed in the low of the panel it partially obstructs water and debris. The low of the panel is skinny and the fastener takes up most of that space. As the water drains it will go over the screw. Screws that have backed out over time or that were installed incorrectly will leak. You will avoid the bulk of this issue by installing the fastener in the high of the roofing panel.

⅞” Corrugated Screw Location For Metal Roofing

A screw line is a row of screws that is spaced at a specific distance from the next row of screws. There will be four screws per screw line placed in the high of the corrugated panel. The screws are spaced out so that every third corrugation has a screw.

FOLLOW US ON SOCIAL MEDIA:

FACEBOOK:

INSTAGRAM:

TWITTER:

LINKEDIN:

HOUZZ:

PINTEREST:

YOUTUBE:

There was one thing we forgot to address in this video. It’s an optional addition as the screw placement shown in the video will work fine. When you are installing the first and last sheet it’s a good idea to add one extra screw in the low of the corrugated panel at both sides of the gable. It’s located within the FIRST SHEET PLACEMENT OF THE LINKED VIDEO at about the five minutes and 35 second mark.

https://www.youtube.com/watch?v=hQM-bDFm-PE

I saw that! Thanks for the heads up! 🙂

This is what I was looking for. Wonderful Explanation. Subscribed your channel. Thanks mate.

Happy to help. Good luck on your installation.

Brilliant, just what I needed for DIY job

Glad it helped. Any questions please leave a comment.

This is the normal roof here in nz

Thank you for sharing your video.

Is the recommendation to fasten on the high seam for western rib also?

Derick, Western Rib has a wider low and the screws will go in the low. I have attached a screw placement diagram link.

https://www.cortenroofing.com/docs/pdf/western-rib-screw-placement.pdf?__hstc=187130103.a0187661f72c773f5bf5b6ae0b342094.1589055209040.1599676704423.1599681083514.216&__hssc=187130103.2.1599681083514&__hsfp=1886519386

Going to put a galvanized steel roof on my shed. I hate this video.

This video and the others are so good! I tried to order my trim through you but the lady confused me, I had already bought corragated locally. I’m hoping to buy land in the next year, if I do I’m going with metal on the cabin.

I am glad the videos helped you. When you are ready for your next job give us a call and we will give you a great price.

Three words: Fantastic! Thank you!

The screws in this video don’t match the tin, and for this reason I’m out.

In instances in which the screws are not the same color as the tin it’s done so you can see the screws better. It’s hard to get a good visual with a white panel and a white screw.

Thank you Ryan for releasing a great product as this [ Check Details Here?> *WoodBlueprints. Com* ]. Most of the plans I have imagined in my mind are put down on your woodworking plans. This is more like a genius job. I love it!?

I have an approximately 45 foot x 10 foot (ridge to eave) awning. If I’m looking to install western rib, is it preferable to order single 10 foot panels or, for example, a 6 foot panel and a 4’6″ panel, overlapping them to prevent any unnecessary cutting with small imperfections in the awning dimension?

Derek, It’s always better to NOT have an overlap if you can avoid one. We will make the panels whatever length that you need.

Can I put a metal roof over top of a rubber roof?

I replayed the video for the background music.

wooden purlins?

Metal roofing is normally installed on a wood substrate or metal purlins. Usually “Cee” purlins. Here’s a link:

https://www.westernstatesmetalroofing.com/galvanized-metal-c-purlins.html

I have a very old garage that I’m roofing to be a chicken house. The roof is arched (slightly). Do I lay the sheets sideways for an arch? Bottom one first?

@Metal Roofing Learning Channel thank you

The sheets will only curve the easy way, but that might mean the water drains the wrong way. Nobody will curve a small job for you. Good luck with the project.

Awesome video thanks

No problem ?

Very good

Un saludo y gracias

Hi, an outstanding set of videos. Clear and easy to understand. I am particularly pleased to learn about the foam strip that fits between the fascia and the roof. I live in a rural location in New Zealand and have been looking for a solution to stop small birds getting into the roofspace via that open gap. Problem solved. Now to check if local building reg’s allow the foam and then where to get it over here. Do you export perhaps?

@Mitchell Lee as a ‘belt and braces’ type of person I would use tape and would lap by 2 or even 3.

It’s called profile foam in NZ. You can buy it from the roof manufacturers but it’s made by ampelite or ansylite depending on your roof. It’s about $5 a metre.

Side note I’m blown away by the differences in best practice between USA and NZ. One example is that we only lap our sheets one corrugation and don’t use butyl tape.

Allan, I appreciate the positive feedback. We could ship the foam closures to New Zealand, but it would be expensive. Here are your two best options: A. Call a metal roofing manufacturer and if they sell to the public they will have the foam in stock. B. Call your local roofing supply center as they normally have access to this. Have a great day.

thanks for sharing