EGGER Roofing Board – Installation instruction

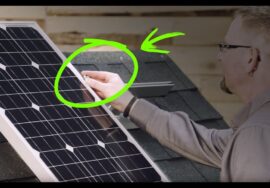

The EGGER Roofing Board is the ergonomic solution for fast and safe roof decking. Mainly developed for the Eastern European market. The small EGGER OSB 3 panel has a special profiling over the edges, which allows fast, precise and truly endless installation as rigid roofing underlay. This film shows the installation step by step.

www.egger.com/roofingboard

What type of board did you use? OSB or CDX plywood, and what thickness?

Great, thank you for the response and additional information.

Hello Emiliy Nicole Williams,

thank you for your request.

Our EGGER Roofing Board is made from EGGER OSB. In the video we show an installation with a board of 12 mm thickness. We also offer the board with 15 and 18 mm thickness. The thickness that shall be applied depends on the rafter span, roof slope and the load capacity (for example snow). Further information concerning the ideal board thickness can be found online in our brochure on http://ms.spr.ly/6052T6A7o.

Your EGGER Social Media Team

buenos videos

construccion

#1

I have a strong experience in the field of wooden houses and I have been working for more than 10 years and I want to travel to any European country or to Australia to work. I want to get to work

Seems good so far! Was easy to talk to about his My Shed Plans [Go Here=> *WoodBlueprints. Com* ]. Guided me in the right direction & helped me understand everything & in the end it was what I wanted

That looks like particle board .

interesting points ,if anyone else trying to find out backyard storage sheds plans try *WoodBlueprints. Com* Ive heard some decent things about it and my colleague got cool success with it.

+1 Like, because effort

Screws on roofs plywood not landing on rafters. Is this the way this works

Hello Brian Pysher,

thank you for your question about the Roofing Board. Screws must always be fixed into rafters, penetrating the board. The difference of the Roofing Board compared to plywood, sawn timber or standard OSB is that it is the only roof decking product that allows the panel’s connection on the short side to occur “in-between“ rafters as well – independent on rafters position or spacing.

You can find more information here: http://ms.spr.ly/6053T3eL1

Best regards,

Your EGGER Social Media Team

А где же обрешётка?

Good job liked

Дом. Четка,

Merhaba fiyat ne kadar adet

@EGGER Group

I have a strong experience in the field of wooden houses and I have been working for more than 10 years and I want to travel to any European country or to Australia to work. I want to get to work

Dear Mr. Hasan Karabulut,

thank you for your request.

Our area sales manager is responsible for price information.

If you like, you can send me your contact details and I will forward them to him.

He will then contact you personally and inform you about the product.

Best regards,

Your EGGER Social Media Team

Lot of innovative building materials and techniques have come from Europe (where they have less material to waste in construction than we do in the US), but I don’t know how that unsupported end seam would pass code here.

Dear Samuel T,

thank you very much for your comment. That’s right, our EGGER Roofing Board was mainly developed for the Eastern European market. Based on your comment, we adjusted the video description once again so that it can be seen immediately.

Best regards,

Yours EGGER Social Media Team

How much weight can the unsupported OSB seam hold? What if there is a bit of warpage in the sheets? Is this approved by any building code?

Dear Mr. Lopez,

Due to the unique combination of shiplap joint on the long edges and tongue and groove profile on the short edges, it is possible to place the joint also between the rafters. It is tested as safe for a point-load of 100 kg between the rafters, up to cc-span 600 mm according to EN 12871.

If you want to find out more about the EGGER Roofing Board visit http://ms.spr.ly/6057rASmJ

Best,

EGGER Social Media Team

1ARM_65 The code does allow for alternate materials and methods with proper documentation, testing etc. but floating joints I don’t think so

Hello 1ARM_65,

thank you for your request.

We are doing performance tests for Roofing Board to ensure high-quality products. We recommend typical horizontal panel joints, no T-joints and no flying joints, on the rafters. Our Roofing Boards are tested as safe for pointload with 100 kg man load between the rafters up to cc-span 600 mm according to EN 12871.

Generally, there should be no warpage in our panels. For possible tolerances (like warpages) of OSB used in building constructions there should be an official standard in each country.

For further questions please contact our technical support team directly via e-mail buildingproducts@egger.com – they are happy to help!

All the best, your EGGER Social Media Team

Really. A end seam not on a 2/4 or anything really.

I don’t care if edge is T&G

I have seen codes and mfg saying certain things are of to look at job a year later and roof looks like a ocean wave.

T&G on 8 ft runs gets rid of H clips and that’s good but not on 4 ft seams

Dear Mike Sacco,

thank you for your comment.

Our EGGER Roofing Board is not comparable with products of other manufacturers.

There is a shiplap joint on the long side of the board and not a T&G. Therefore existing regulations or processing recommendations of other products can’t be applied.

In the past years many projects have been realized with the EGGER Roofing Board and so far we are not aware of any problems with wave-shaped deformation. We attach great importance to the high quality and stability of our wood-based materials.

For further questions please contact our technical support team directly via e-mail: buildingproducts@egger.com – they are happy to help.

Best regards,

Yours EGGER Social Media Team

Whats the blue stuff

Ok

Dear Ruben Varela,

thank you for your question.

The blue layer is an underlay membrane.

Best regards,

Yours EGGER Social Media Team

buenos videos

construccion

work #1